H. Ling

Department of Food Science and Technology, Gansu Agricultural University, Lanzhou 730070, P.R. China

A nutritional and healthy food is manufactured from a combination of bone marrow and bone powder of Tianzhu White yak, wheat and soybean flour, and additives. The food contains 11.5% of protein, 3400 Kcal/kg of energy, 23 g/kg of calcium and 639.9 mg/kg of iron. High pressure, decompression and condensation protocols are used to extract the bone marrow. Extrusion and expansion approaches increase dissolubility of α-starch from wheat.

Keywords: Bone marrow powder, manufacture protocol, quality, Tianzhu White yak

To better use the resource of Tianzhu White yak, this study develops a protocol to produce a nutritional and healthy food product consisting of bone marrow powder from the yak bone, wheat, soybean and additives. This paper reports a detailed protocol for the manufacture of the product.

Fresh bone collected from the Tianzhu White yak feeding on the natural pasture at an altitude of 3400 metres above sea level (masl), wheat, soybean and vegetable oil (purchased from selected commercial markets), and additives (gingeli, peanut, salt, monosodium glutamate and others) are used as raw materials. Compound aluminum foil bag is used as packaging material for the finished product.

Multiple bulking machine (SDP-90), muller (45A-80), mixing machine (DF), granule machine (YK-160), puffed food firing machine (YHW), automatic granule package machine (DXDK150II), autoclave (GT7C5), decompression and condensation pan (MZN-500), and store pot (GRJC-G600) are used in the processing protocol. Based on the daily nutritional requirement of an adult person as recommended by the Chinese Association of Nutrition, intake and interactions among the nutrients, the formula is developed and screened by taking into consideration necessary solubility properties. It consists of 14% condensed bone marrow solution, 63.5% bulked wheat flour, 10% bone powder, 10.5% additives and 2% vegetable oil.

Condensed bone marrow solution is made from the bone by washing, breaking up, extraction under high temperature and pressure, and condensation through decompression. The fresh bones, especially the vertebras and other tubule bones of the Tianzhu White Yak are selected and dipped in the water for 2–4 h to remove the blood residue. To be easily broken up, the washed bones are frozen at –20°C for 3–4 h and then autoclaved with a ratio of the broken bone to water of 1:0.5 under 0.25–0.3 Mpa and 121°C for 4 h to extract the bone marrow. The solution is filtered and transferred to the decompression and condensation pan for condensation under –0.06 Mpa and 60–70°C for 2–3 h to make 94% of the water vaporised. The rest is the condensed bone marrow solution, which accounts for about 33% of the fresh bone weight.

The bone residue after bone marrow extraction is used to make bone powder with a granularity smaller than 70 mm through milling, drying, grinding and sifting.

A mixture of wheat and soybean flour is prepared by extrusion, expansion, grinding and sifting. First, the wheat and soybean is desquamated after adding water to a humidity of 10–14% and transferred to the puffed food-firing machine which is maintained at 160 ± 10ºC. The mixture is melted under 3–8 Mpa and 200°C, expanded by sudden release to the normal pressure, and solidified under 80°C. Then it is grounded by the muller and screened into powder smaller than 60 μm.

The finished product is prepared according to the formula above after mixing, granulating into 1.5 mm3 size, drying at 80–85°C for 2–3 h, weighing and packing into bags weighing 30 g each.

The protein, fat, dry matter, energy, minerals, expansion (area of cross section of the bulked granule to area of machine matrix), viscidity (valued in Mpas after dissolving the product in water at a ration of 1:8), dissolubility (percentage of undissolved dry residue in the 10 g product dissolved in water at a ration of 1:9 at 90°C for 10 min), and related quality (hygiene) indexes are measured.

The finished product is yellow-brown in colour and has a very nice flavour of baked wheat and faint scent. The granules are very uniform in size and dissolubility is very high with a viscidity of 61.5.

Both the building up condition and dissolubility of the finished product are improved by the extrusion, expansion and granule-making procedures. After being puffed, the starch of wheat is fully converted into a-form with plenty of -OH groups that are easy to combine with more water to improve the viscidity of dissolved product.

The dry matter, protein, fat, energy, calcium, iron and zinc contents are 86.7%, 11.52%, 20.26%, 3,400 Kcal/kg, 23 g/kg, 639.9 mg/kg, and 10.82 mg/kg, respectively. The protein, energy, calcium and iron contents are higher than those in common plant-based foods and milk. The higher energy is particularly helpful for nomads living at high altitude, under cold temperatures and high humidity. All the quality (hygiene) indexes match national and international standards.

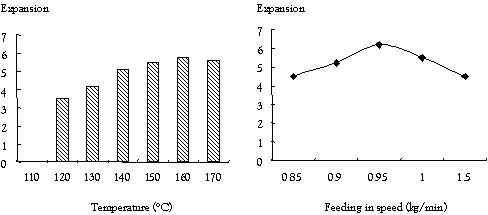

The optimum warming up temperature of the matrix and feeding in speed of the mixture are 160°C and 0.9–1.0 kg/min (Figure 1).

Figure 1. Effects of the warning up temperature of the matrix and feeding in speed on expansion of the mixture of wheat and soybean flour.

It is well known that protein content in wheat is relatively low, and the amount of the essential amino acids is limited. However, the soybean is rich in protein but has a high fat content, and this presents a problem during the bulking treatment. An attempt has been made to try to optimise the ratio of wheat to soybean in the mixture. The ratio of 9:1 has been found to be the optimum for bulking effectiveness (Table 1).

Table 1. Effect of ratio of soybean to wheat on the expansion of the mixture.

Soybean : wheat |

10:90 |

15:85 |

20:80 |

25:75 |

Effectiveness |

Good |

Good |

Better |

Oil |

Expansion |

5.8 |

5.1 |

4.0 |

2 |

The new product developed from the Tianzhu White yak is a natural, healthy food. It is full-bodied and is in accord with the standards of traditional food habit of the local Tibetan nomads. Popularisation of this product for its expanded use provides a means of increasing the use the natural yak resource and for increasing the income of the yak herders in the region.

To summarise the manufacture protocol, the optimum parameters for the warming up temperature of the matrix is 160°C, the feeding in speed of 0.9–1 kg/mi and ratio of wheat to soybean 9:1. The size of the bulked granule is 1.5 mm3 and the condition to extract the bone marrow is 0.25–0.3 Mpa and 121°C for decompression, and –0.06 Mpa and at 60–70°C for condensation, by which a 33% concentrated bone marrow solution is harvested from the total fresh yak bones.